-

I-Melt Polymer Candle Filter for High Viscosity Substances Filtration

Isihlungi sekhandlela se-polymer esincibilikayo siyingxenye ebalulekile esetshenziswa embonini ye-chemical fiber ukuhlunga ukuncibilika kwe-polymer.I-polymer melt iwuhlobo oluncibilikisiwe lwama-polymers okwenziwa, asetshenziselwa ukukhiqiza izinhlobo ezahlukahlukene zemicu yamakhemikhali njenge-polyester, inayiloni, ne-acrylic.

Injongo eyinhloko yesici sesihlungi esincibilikayo ukususa ukungcola, njengezinhlayiya eziqinile nokungcola, ku-polymer encibilikayo ngaphambi kokuba iphinde icutshungulwe ibe imicu.Lokhu kungcola kungaba nomthelela omubi kwikhwalithi yemicu yokugcina yamakhemikhali futhi kubangele izinkinga zokukhiqiza njengokungalingani, amaphutha, nokuncipha kwezakhiwo zemishini.

Isici sokuhlunga esincibilikayo sifakwe kulayini we-extrusion, lapho ukuncibilika kwe-polymer kuphoqelelwa ngesihlungi ukuze kukhishwe ukungcola.Ukuncibilika kwe-polymer ehlungiwe bese kuqhubekela enqubweni yokuphotha, lapho kuqiniswa khona kube imicu eqhubekayo noma imicu eyisisekelo.

Ukugcinwa njalo kanye nokushintshwa kwesici sokuhlunga esincibilikayo kubalulekile ukuze kuqinisekiswe ukusebenza okuqhubekayo nokusebenza kahle kwenqubo yokukhiqiza i-fiber yamakhemikhali.Lokhu kusiza ukugwema ukuphelelwa yisikhathi kokukhiqiza, ukuthuthukisa ikhwalithi yomkhiqizo, nokuqinisekisa ubude besikhathi semishini yokuhlunga. -

Isihlungi Samafutha Ensimbi Engagqwali ku-Metal Media

Ukuhlunga uwoyela kuyinqubo yokukhipha ukungcola nokungcola emafutheni, okuwuvumela ukuthi usetshenziswe kabusha noma ugaywe kabusha.Isetshenziswa kakhulu ezimbonini ezifana nezezimoto, ezokukhiqiza, neziphehla ugesi.

Kunezindlela eziningana zokuhlunga uwoyela, okuhlanganisa:

Ukuhlunga ngomshini: Le ndlela isebenzisa izihlungi ezenziwe ngezinto ezifana nephepha, indwangu, noma i-mesh ukuze icuphe ngokomzimba futhi isuse izinhlayiya eziqinile emafutheni.

Ukuhlunga kwe-Centrifugal: Kule nqubo, uwoyela uphothwa ngokushesha ku-centrifuge, okwenza ukujikeleza kwesivinini esikhulu okuhlukanisa izinhlayiya ezisindayo kuwoyela ngamandla amakhulu.

I-vacuum dehydration: Le ndlela ihilela ukuveza uwoyela endaweni engenalutho, eyehlisa indawo abilayo yamanzi futhi iwabangele ukuba ahwamuke.Lokhu kusiza ukususa amanzi kanye nomswakama emafutheni.

Ukuhlunga uwoyela kubalulekile ekugcineni ukusebenza nempilo yemishini encike ekugcotshweni kukawoyela.Kuyasiza ukuvimbela ukwakheka kwe-sludge namadiphozithi, kuthuthukisa i-viscosity kawoyela nokuzinza kokushisa, futhi ivikela izingxenye ezibalulekile ekugugeni nasekulimaleni. -

Isihlungi Segesi Yensimbi Engagqwali Kumidiya Yensimbi

Umgomo wokuhlunga igesi ukuqinisekisa ukuthi igesi ecutshungulwayo noma esetshenziswayo ihlanzekile futhi ayinazo izinhlayiya, izinto eziqinile, uketshezi, nokunye ukungcola okungahlehlisa izinga legesi noma kuthinte ukusebenza kahle nokusebenza kwemishini noma izinqubo esetshenziswayo. phakathi.

Ukuhlunga kwegesi kungafinyelelwa ngezindlela ezihlukahlukene nobuchwepheshe, kuye ngezidingo ezithile kanye nezinhlobo zokungcola ezikhona.Amanye amasu ajwayelekile ahlanganisa:

Ukuhlunga Kwezinhlayiyana: Lokhu kuhilela ukusebenzisa izihlungi ukuze ucuphe ngokomzimba futhi ukhiphe izinhlayiya eziqinile kanye nezinhlayiya ezivela emfudlaneni wegesi.Izihlungi zingenziwa ngezinto ezifana ne-fiberglass, i-polypropylene, noma insimbi engagqwali, futhi zikhethwa ngokusekelwe kusayizi nohlobo lwezinhlayiya ezizosuswa.

I-Coalescing Filtration: Le ndlela isetshenziselwa ukususa amaconsi awuketshezi noma inkungu kumagesi.Izihlungi ezihlanganisayo ziklanyelwe ukuthwebula nokuhlanganisa amaconsi amancane oketshezi abe amakhulu, okuwavumela ukuthi akhishwe kalula noma ahlukaniswe nomfudlana wegesi.

Ukukhethwa kwendlela yokuhlunga kanye nemidiya ethile yesihlungi noma ubuchwepheshe kuncike ezintweni ezifana nokwakheka kwegesi, izinga lokugeleza, ukucindezela, izinga lokushisa, kanye nezinga elifiswayo lokuhlunga. -

Ikhatriji Yesihlungi Sensimbi Engagqwali

I-cartridge yesihlungi sensimbi engagqwali iyikhatriji yokuhlunga eyenziwe ngezinto zensimbi engagqwali, esetshenziselwa ukuhlunga ukungcola oketshezini noma kugesi.Ama-cartridges okuhlunga insimbi engagqwali anezinzuzo zokumelana nokugqwala, ukumelana nokushisa okuphezulu, ukumelana nokucindezela, njll., futhi asetshenziswa kakhulu ekuhlungeni uketshezi, ukuhlungwa kwegesi, ukuhlukaniswa koketshezi oluqinile nezinye izinqubo emkhakheni wezimboni.Ingakwazi ukususa ngokuphumelelayo izinhlayiya ezimisiwe, ukungcola, ama-sediments, njll., futhi ithuthukise ukuhlanzeka kanye nekhwalithi yoketshezi.Amakhatriji okuhlunga ensimbi engagqwali ngokuvamile anesakhiwo sezendlalelo eziningi futhi agcwaliswa ngesihlungi semidiya yokunemba okuhlukile.Ukunemba okufanele kokuhlunga kanye nobukhulu kungakhethwa ngokuvumelana nezidingo zangempela.Ngenxa yokuqina nokuhlanza okulula kwezinto zensimbi engagqwali, ama-cartridges okuhlunga insimbi engagqwali angasetshenziswa ngokuphindaphindiwe futhi abe nempilo ende yesevisi.

Ama-cartridge we-stainless steel filter asetshenziswa kakhulu kumakhemikhali, uphethiloli, imithi, ukudla, isiphuzo, ukwelashwa kwamanzi nezinye izimboni. -

Isihlungi sekhandlela le-Sintered Wire Mesh

Isihlungi se-sintered wire mesh saziwa ngokusebenza kahle kokuhlunga, amandla aphezulu okubamba ukungcola, nokumelana nokugqwala namazinga okushisa aphezulu.Ivame ukusetshenziswa ezimbonini ezihlukahlukene, ezifana nowoyela negesi, ukucubungula amakhemikhali, imithi, ukudla nesiphuzo, nokwelashwa kwamanzi.

Isihlungi sidizayinelwe ukususa ukungcola, okuqinile, nokungcola kuketshezi noma umfudlana wegesi.Ingasetshenziswa kukho kokubili izinhlelo zokusebenza zokuhlunga uketshezi kanye negesi, inikeze ukusebenza kokuhlunga okuthembekile nokungaguquki.Isihlungi se-sintered wire mesh siyakwazi ukugcina izinhlayiya phansi kumasayizi ama-sub-micron, kusenze silungele izinhlelo zokusebenza lapho kudingeka ukuhlunga okuhle.

izihlungi ze-sintered wire mesh ziyizixazululo ezisebenza kahle kakhulu nezithembekile ezihlinzeka ngokusebenza okuhle kakhulu nempilo ende yesevisi ezinhlobonhlobo zezinhlelo zokusebenza zezimboni. -

Hlunga Ubhasikidi kanye nesihlungi se-Conical

Ubhasikidi wokuhlunga iyisisetshenziswa esisetshenziselwa ukuhlunga okuqinile oketshezini noma kumagesi.Ngokuvamile iqukethe isitsha noma umkhumbi omise okwebhasikidi onezinto ezimbobozelayo, njenge-mesh noma insimbi enembobo, ukuze ubambe okuqinile kuyilapho uvumela uketshezi noma igesi ukuthi igeleze.

Obhasikidi bezihlungi bavame ukusetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi ukukhiqiza, uwoyela negesi, ukudla nesiphuzo, nokwelashwa kwamanzi.Avamise ukufakwa emapayipini noma emikhunjini ukuze kukhishwe udoti, izinhlayiya, noma ukungcola emgudwini woketshezi.

Isihlungi esiyikhonikhi wuhlobo lwedivayisi yokuhlunga enomumo oyikhonikhali.Iklanyelwe ngokukhethekile ukuhlunga uketshezi noma amagesi futhi isuse ukungcola noma izinhlayiya kuzo.

Ukuma kwe-conical kwesihlungi kunenzuzo njengoba kuvumela ukuhlunga okuphumelelayo futhi kukhulisa indawo engaphezulu etholakalayo ukuze uxhumane noketshezi.Lo mklamo ukhuthaza ukucupha okusebenzayo noma ukugcinwa kwezinhlayiya kuyilapho uvumela uketshezi oluhlungiwe ukuba ludlule. -

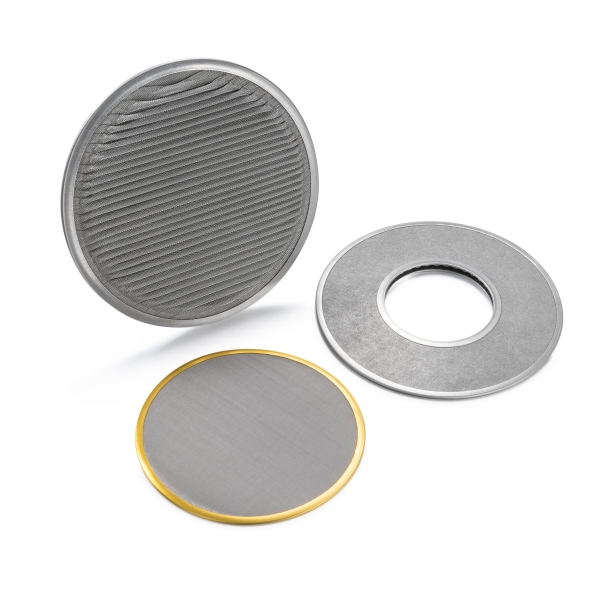

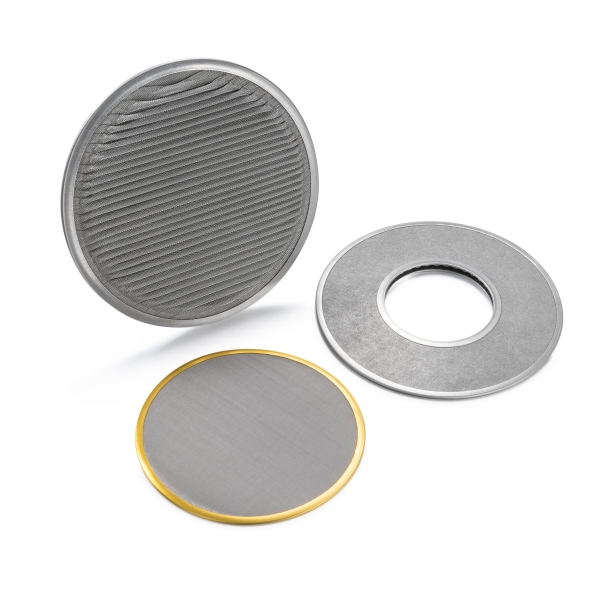

Izihlungi Zediski Leaf Zokuhlunga Kwefilimu Ye-Polymer

Amafilimu e-polymer anohlu olubanzi lwezinhlelo zokusebenza ngenxa yezakhiwo zawo futhi avame ukusetshenziswa ezimbonini ezifana nokupakisha, i-electronics, izimoto, kanye ne-biomedical njengezingubo zokuzivikela, izendlalelo zesithiyo, i-encapsulation yedivayisi ye-elekthronikhi, noma njengama-substrates ezibonisi eziguquguqukayo.

Njengoba ifilimu ye-polymer ibhekisela eshidini elincanyana noma i-coating eyenziwe nge-polymer material.Inhloso eyinhloko yezihlungi ze-leaf disc ekuhlungeni ifilimu ye-polymer ukususa ukungcola, ukungcola, nezinhlayiya ezivela ku-polymer encibilikayo noma isisombululo ngaphambi kwenqubo yokubunjwa kwefilimu.Lokhu kusiza ukuqinisekisa ukukhiqizwa kwamafilimu e-polymer asezingeni eliphezulu nangenasici.

-

I-Metal Powder yokuhlunga kwe-Polymer

Impushana yensimbi etholakala ngosayizi abahlukene bezinhlayiyana ezenziwe ngezinto ezihlukene, njenge-nickel, i-chromium, i-silicon, iManganese inamandla aphezulu kanye nokuzinza kwamakhemikhali aphezulu njengemidiya yokuhlunga ngesikhathi sokuphotha kwe-polyester ne-polyamide.Isihlabathi sensimbi engagqwali i-Futai sinomumo ongavamile owengeziwe onezici eziningi ezingaphezulu ukuze uthwebule ngempumelelo futhi ugcine izinhlayiya ezivela ku-polymer encibilikisiwe ukuze kuncishiswe i-clog yama-spinnerets nokuphuka kwentambo.

Ukukhethwa kwezimpushana zensimbi engagqwali zokuhlunga kwe-polymer kufanele kucabangele izici ezinjengokuhambisana nempahla ye-polymer, ububanzi bezinhlayiyana ezifunekayo, ukusebenza kahle kokuhlunga, nanoma yiziphi izidingo zamakhemikhali noma zemvelo.

-

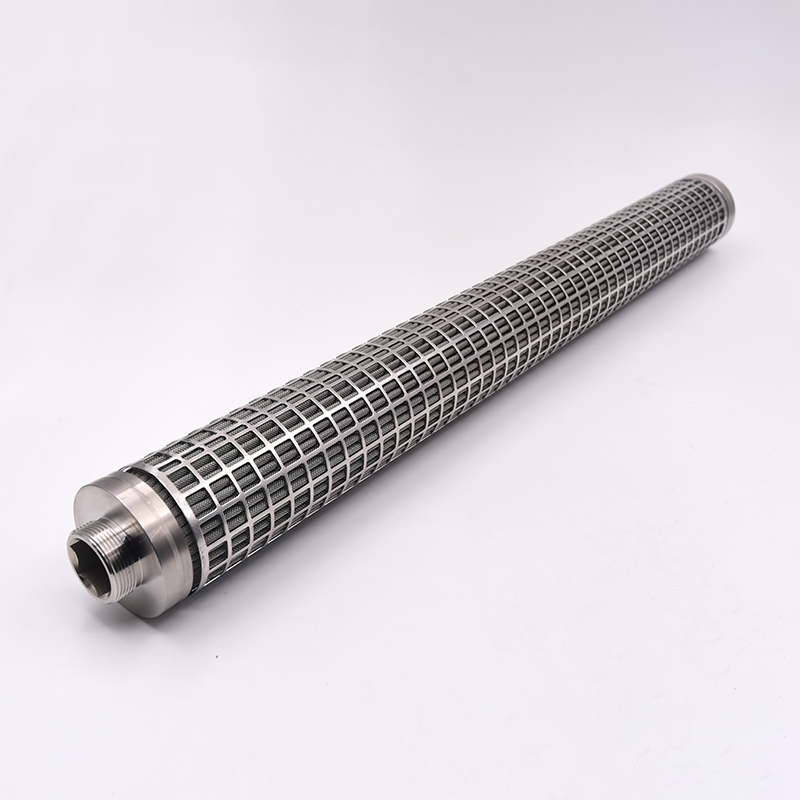

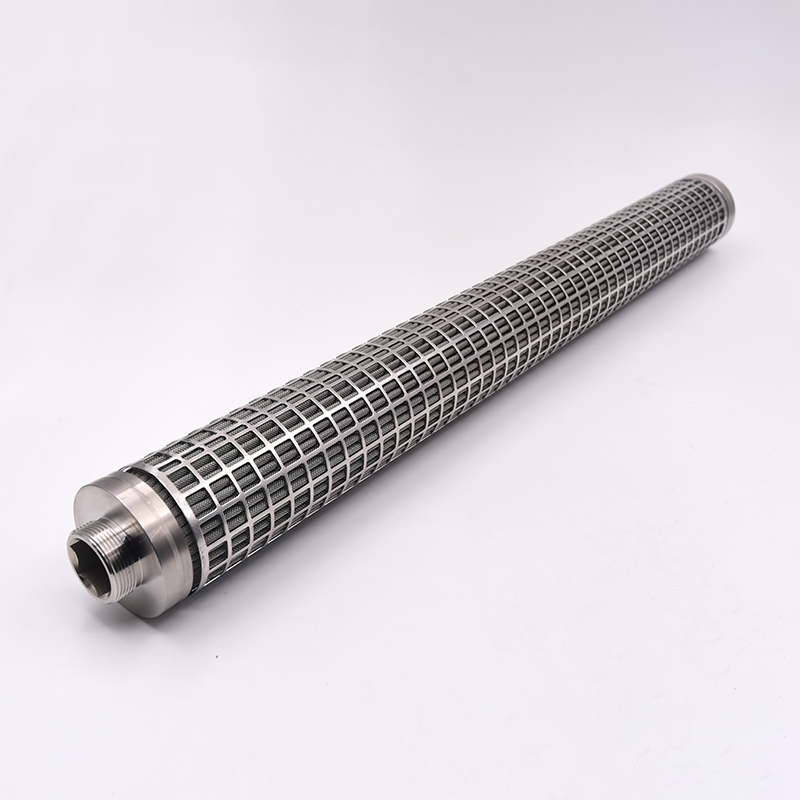

Isihlungi se-Spin Pack ku-Metal Media

Isihlungi se-spin pack kumidiya yensimbi siwuhlobo lwesihlungi esisetshenziswa ezimbonini ezahlukahlukene, ikakhulukazi ezinqubweni zokukhiqiza i-polymer.Isixazululo singaba uwoyela, igesi, amanzi, amafutha, uketshezi, i-polymer nanoma yiluphi uhlobo lwesisombululo esigelezayo kunoma yiliphi izinga lokushisa.Iqukethe i-mesh yensimbi yensimbi noma isikrini esiphothwa sibe yinoma yimuphi umumo, njengesilinda, unxande, isikwele, umumo oval noma okunye.Lesi sihlungi sephakethe sifakwe ohlelweni lokuhlunga ukuze kukhishwe ukungcola nezinhlayiya esixazululweni.Imidiya yensimbi inikeza amandla aphezulu nokuqina, okuvumela isihlungi ukuthi simelane namazinga okushisa aphezulu nezingcindezi.