I-Metal Powder yokuhlunga kwe-Polymer

Umlando Wokuthuthukiswa Kwe-Metal Powder Ye-Polymer Filtration Media

I-polymer ephezulu ye-PET PA PP encibilikisiwe idinga ukuhlungwa ngaphambi kokuba i-chemical fiber iphothe ukuze isuse ukungcola nezinhlayiya zejeli ezifakwe ekuncibilikeni ukuze kuvinjelwe ukuxhunywa kwembobo ye-spinneret, ithuthukise ikhwalithi ye-PET PA filament fiber, njengezintambo ze-POY FDY. ;lapho i-polymer encibilikayo igeleza kusendlalelo sesikrini se-spin pack, ukumelana kuyakhiqizwa, ukuze ukungqubuzana okuncibilika kukhiqize ukushisa, izinga lokushisa liyakhuphuka, futhi izici ze-rheological zokuncibilika ziyathuthukiswa.Ngesikhathi esifanayo, ukuncibilika kuhlanganiswe ngokugcwele ukuvimbela umehluko we-viscosity phakathi kokuncibilika;ukuncibilika kusakazwa ngokulinganayo emgodini ngamunye omncane we-spinneret;ngokwanda kwesikhathi sokusetshenziswa kwesihlungi se-spin pack, ukungcola okusengqimbeni lesihlungi se-mesh pack kuzokwanda, futhi ukucindezela komhlangano kuzokhula kancane kancane.Isivinini sokwanda kwengcindezi siyashesha, futhi impilo yesevisi yomhlangano imfushane.Lapho umhlangano ukhuphukela ekucindezelweni okuthile, kuyadingeka ukufaka esikhundleni somhlangano ngesikhathi, ngaphandle kwalokho, ipompo yemitha iyachotshozwa, noma i-spinneret ikhubazekile, noma ukuvuza kwenzeka.

Ukukhethwa kwezingxenye zokuhlunga ezifanele kubaluleke kakhulu ekuphotheni kwefayibha yokwenziwa, futhi imidiya yokuhlunga izinhlayiyana efanelekile ibaluleke kakhulu.Enqubweni yokuthuthukiswa kokuphotha, futhi kuyinqubo yokuthola indawo yokuhlunga ye-shear ekahle.Izinto eziningi zokuhlunga ezaziwayo zifaka isihlabathi sasolwandle, ukushefa kwensimbi, ubuhlalu bengilazi, amapuleti ensimbi anezimbotshana ezinezimbotshana, kanye nezinhlayiya zensimbi ezimise ngendlela engavamile.

Ngaphezu kokungabizi, indawo yokuhlunga efanelekile kufanele ibe futhi kufanele igcine i-porosity ephezulu ezingcindezini ezihlangatshezwana nazo ngesikhathi sokuncibilika kwe-polymer.Ukuze kugcinwe i-porosity ephezulu, umbhede wezinhlayiya zama-polymers amaningi ashisayo uwumkhuba wokwenza ijeli eqoqana futhi inciphise ukusebenza kahle kokuhlunga kwemidiya yokuhlunga.Ngakho-ke, izinto zokuhlunga zensimbi akumele zifake isandla ekwakhekeni kwejeli.

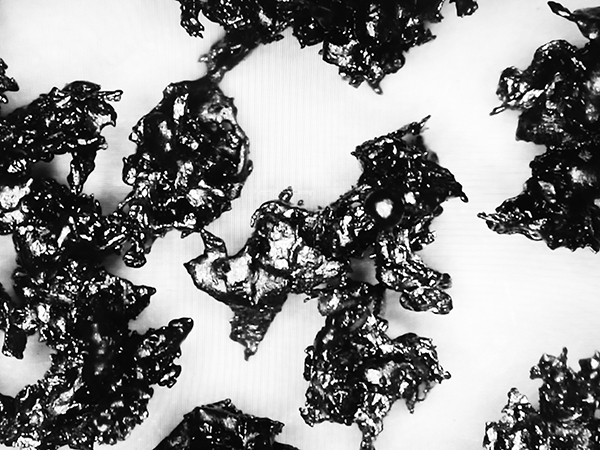

Itholakala kakhulu ukuze uthole isihlabathi sasolwandle, kodwa i-brittle ngokwedlulele ngomphumela wokuthi ukuthuthukiswa kwezinhlayiya ezinhle kuvame ukuvimbela ama-capillaries kuma-spinnerets.Ukwengeza, indawo ethize yesihlabathi sasolwandle iyancipha kakhulu futhi ingaphansi kwephesenti le-porosity yanoma iyiphi ivolumu yesihlungi sephakethe, ngakho-ke ukucindezela kwephakethe kuzokhuphuka kakhulu.Impushana yensimbi engagqwali elungiswa ngaphansi kwezimo ezithile ibonisa indawo engavamile ngokwedlulele ethi ngokufanele ukuminyana okusobala okuphansi, ivame ukuthuthukisa ukusebenza kahle kokuhlunga kwayo;ngaphansi kwengcindezi yokusebenza, ikhombisa kokubili ukuminyana okusobala futhi ithuthukise ukumelana nokucindezelwa ukuze kusebenze kahle ukuhlunga ngokuguquguquka okuncane noma okungekho nhlobo kwezinhlayiyana kanye nokuwa.

Ukukhethwa kwe-FUTAI ye-Stainless Metal Powder

I-FUTAI iphakamisa isihlabathi se-serial yensimbi engagqwali ye-F-01 ye-polyester POY FDY filament spinning njengemidiya yokuhlunga kwezomnotho;Ukuze kuthuthukiswe ikhwalithi yentambo, i-FUTAI incoma i-S-03, amandla aphezulu emishini kanye ne-oxidization encane ebucayi yensimbi powder;Ukuze kusetshenziswe ukucindezela okukhulu kwasekuqaleni, i-S-04 iyinketho efiselekayo ngenxa yokumelana kwayo okuthuthukisiwe kokucindezelwa, ukungena kakhulu ekuncibilikeni kwe-polymer, ikakhulukazi ekusetshenzisweni kwe-PA filament spinning.

Uhlobo Lwe-Stainless Steel Powder

| Uhlobo | Fe(%) | I-Ni(%) | Cr(%) | Mn(%) | Si(%) | Mo(%) | C(%) | Izinhlelo zokusebenza |

| F-01 | U-Bal. | Ubukhulu.0.6 | 16-18 | Ubukhulu.1.0 | 1.0-4.0 | - | Ubuningi.0.12 | Economic metal powder |

| S-03 | U-Bal. | 6-12 | 16-22 | Ubukhulu.1.0 | 0.6-3.5 | Ubukhulu.3.0 | Ubukhulu.0.12 | Imidiya ejwayelekile |

| S-04 | U-Bal. | Ubukhulu.0.6 | 33-37 | Ubukhulu.1.0 | 2-4 | - | Ubukhulu.0.12 | Imidiya ephezulu |

Izinzuzo

1. Amandla aphezulu emishini.

2. Ukumelana nokuqina okuphezulu.

3. Ukungalungi okuphakeme.

4. I-porosity ephezulu.

5. Kuncibilika kakhulu ku-polymer.

6. Isikhathi eside sokuphila se-spin pack.

7. Ikhwalithi engcono yentambo.

Usayizi We-Mesh Otholakalayo Nezakhiwo Zawo Zomzimba

Lapho ucubungula ukuphotha kwe-filament, okufana nentambo ye-POY ne-FDY, okubaluleke kakhulu ukuhlanganisa osayizi abambalwa abahlukene bempushana ukuze uthole umphumela ofanele wokuhlunga.I-FUTAI inganikeza wonke amaklayenti ukukhetha okungcono kakhulu kwamasayizi anezikhala ngokusekelwe kokwazi kwethu kumpushana yensimbi engagqwali kanye nolwazi olucebile ekukhiqizeni i-synthetic fiber spinning, ukuze amaklayenti akwazi ukusebenzisa ngokugcwele izinzuzo zesihlabathi sensimbi, andise. impilo yonke ye-spin pack futhi uzuze ikhwalithi enhle yezintambo ze-filament.

Ngemva kwalokhu uhlu lwamasayizi atholakala ngokwe-ISO 4497 INTERNATION STANDARD FOR Metallic powders.Noma yimaphi amanye amasayizi angakhiqizwa ngokucelwa.

| Usayizimicron | UsayiziImeshi | Ukuminyana okusobalag/cm3 | Thepha ukuminyanag/cm3 | I-Porosity % |

| 850/2000 | 10/20 | 1.45 | 1.95 | 75 |

| 500/850 | 20/30 | 1.55 | 2.10 | 73 |

| 350/500 | 30/40 | 1.60 | 2.10 | 71 |

| 250/350 | 40/60 | 1.65 | 2.60 | 67 |

| 180/250 | 60/80 | 1.80 | 2.70 | 65 |

| 150/180 | 80/100 | 2.00 | 2.90 | 62 |

| 125/150 | 100/120 | 2.22 | 3.10 | 58 |

| 90/125 | 120/170 | 2.50 | 3.20 | 56 |