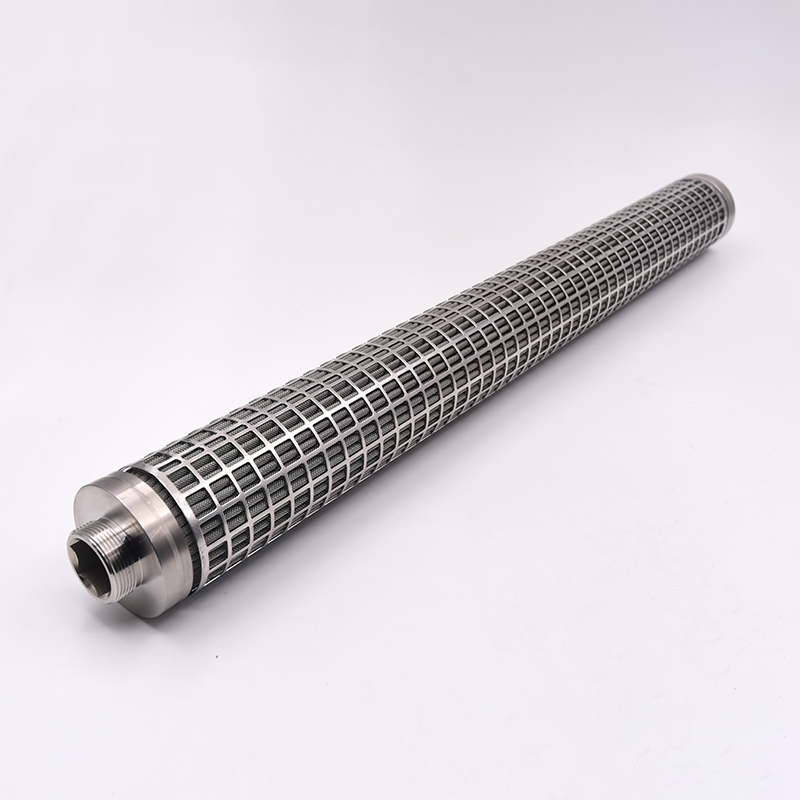

I-Melt Polymer Candle Filter for High Viscosity Substances Filtration

Ncibilikisa isihlungi sekhandlela sePolymer

I-elementi yesihlungi se-Melt iyisici sokuhlunga sensimbi yonke esishiselwe i-argon arc welding.Isendlalelo sesihlungi samukela inqubo yokugoqa yesakhiwo esinemiphetho eminingi, enokusabalalisa kosayizi wezimbotshana ezifanayo kanye nendawo yokuhlunga eyandisiwe.Isihlungi sensimbi senziwe ngensimbi engagqwali ngokuphelele, ngaphandle kokuvuza noma ukuchithwa okuphakathi.Ezimweni ezinengcindezi ephezulu, isihlungi sensimbi engenasici sithatha idizayini yamathambo.Uhlaka lwamathambo lwangaphakathi nangaphandle luthuthukisa kakhulu ukumelana nokucindezela kwesici sokuhlunga sensimbi.Isendlalelo esiyinhloko sesihlungi Sesihlungi Se-Pleated ikakhulukazi sisebenzisa izinto ezimbili: insimbi engagqwali ye-wire mesh ne-stainless steel Sintered fiber.Insimbi engagqwali wire mesh lukwa kusukela insimbi engagqwali.Isihlungi saso esinama-pleated sinezici zezimbotshana ezibushelelezi, ukuhlanzwa kalula, ukumelana nezinga lokushisa eliphezulu, ukumelana nokugqwala, akukho mesh yocingo ewayo, nomjikelezo omude wokuhlunga.I-stainless steel sintered fiber iyisihlungi esijulile esinezimbotshana esenziwe ngemicu yensimbi engagqwali efakwe kumazinga okushisa aphezulu.Isihlungi saso se-pleated sinezici ze-porosity ephezulu, ukungena komoya okuhle, umthamo oqinile wokubamba ukungcola, kanye nekhono eliqinile lokuvuselela.

Isici sokuhlunga i-Melt iyithuluzi lokuhlunga elisetshenziswa kakhulu embonini yamakhemikhali yefiber yokuncibilika kwe-polymer nezinye izinto ezine-viscosity ephezulu.Umsebenzi wayo ukususa ukungcola okuqinile njengezinhlayiya ze-carbonized kanye nama-oxide ensimbi ekuncibilikeni, ukuthuthukisa ukuhlanzeka kokuncibilika, ukuhlinzeka ngezinto zokusetshenziswa ezifanelekayo zezinqubo ezingezansi, nokuqinisekisa ukusebenza okuvamile kwesihlungi esincibilikayo.

Izici Zobuchwepheshe

1. Ukumelana nokushisa okuphezulu, ukucindezela okuphezulu nokugqwala kwamakhemikhali.

2. Ukuphefumula okuhle kakhulu, umthamo omkhulu wokubamba ukungcola, amandla aphezulu, ukubekwa uphawu okuhle, impilo ende, futhi ingahlanzwa futhi isetshenziswe kabusha ukuze isetshenziswe ngokuphindaphindiwe.

3. Indawo yokuhlunga egoqiwe izikhathi ezi-3-5 kunezohlobo lwe-cylindrical.

4. Izinga lokushisa lokusebenza: -60-500℃.

5. Umehluko omkhulu wengcindezi into yokuhlunga engamelana nayo: 10MPa.

Amapharamitha wohlelo lokusebenza ojwayelekile womkhiqizo

1. Ingcindezi yokusebenza: 30Mpa.

2. Izinga lokushisa lokusebenza: 300℃.

3. Umthamo wokubamba ukungcola: 16.9~41mg/cm².

Indlela Yokuxhuma Komkhiqizo

Isixhumi esibonakalayo esijwayelekile (njenge-222, 220, 226) uxhumano lwesikhombimsebenzisi esisheshayo, uxhumano lwentambo, uxhumano lwe-flange, uxhumano lwenduku yokubopha, isixhumi esibonakalayo esenziwe ngokwezifiso.

Izindawo Zokufaka Isicelo

1. I-Petrochemical: Ukucwengwa, ukukhiqizwa kwamakhemikhali kanye nokuhlukaniswa nokubuyiselwa kwemikhiqizo ephakathi.

2. I-Metallurgy: isetshenziselwa ukuhlunga kwezinhlelo ze-hydraulic zezigayo eziginqikayo kanye nemishini yokuphonsa eqhubekayo.

3. Indwangu: Ukuhlanzwa kanye nokuhlunga okufanayo kwe-polyester kuncibilika phakathi nenqubo yokudweba.

4. Ama-elekthronikhi kanye nemithi: ukwelashwa kwangaphambili kanye nokuhlunga kwamanzi e-osmosis ehlanekezelwe namanzi angcolile, ukwelashwa kwangaphambili kanye nokuhlunga koketshezi lokuhlanza kanye ne-glucose.

5. Amandla ashisayo namandla enuzi: ukuhlanzwa kwezinhlelo zokuthambisa, izinhlelo zokulawula isivinini, amasistimu okulawula ama-bypass ama-turbines nama-boilers, ukuhlanzwa kwamaphampu okuhambisa amanzi, amafeni kanye nezinhlelo zokususa uthuli.

More Product