Uhlelo Lokuhlunga lokuhlunga kwe-Melt Polymer

I-Melt Polymer Filtration System

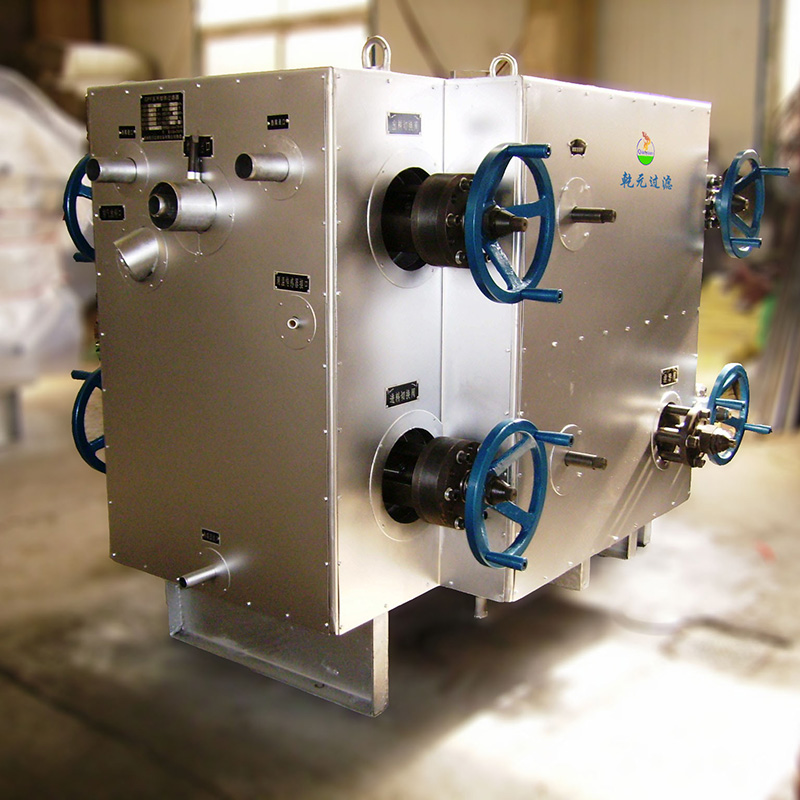

Isistimu yokuhlunga ye-polymer encibilikayo ibalulekile ezinhlelweni eziningi lapho ama-polymer acutshungulwa noma asetshenziswa, njengokukhiqizwa kwemboni ye-polymer ye-PET/PA/PP, i-pre-polymerizaton, i-polymerization yokugcina, intambo ye-filament, i-polyester staple fiber spinning, amafilimu e-BOPET/BOPP , noma ulwelwesi.Lolu hlelo lusiza ukususa ukungcola, ukungcola, kanye nezinhlayiya ezithinta i-viscosity kusuka ku-polymer encibilikisiwe, iqinisekisa ikhwalithi nokuvumelana komkhiqizo wokugcina.

Ukuze kuthuthukiswe ikhwalithi ye-polymer encibilikayo futhi andise impilo yesevisi yezingxenye zepakethe ye-spin, isihlungi esincibilikayo esiqhubekayo (CPF) sifakwa epayipini elincibilikayo eliyinhloko.Ingakwazi ukususa izinhlayiya zokungcola kwemishini ngobubanzi obukhulu kuno-20-15μm ekuncibilikeni, futhi inomsebenzi we-homogenizing ukuncibilika.Ngokuvamile uhlelo lokuhlunga luqukethe amakamelo amabili okuhlunga, futhi ama-valve anezindlela ezintathu axhunywe epayipini lokuncibilika.Ama-valve ezindlela ezintathu angashintshwa ngezikhathi ezithile ukushintshanisa ukusetshenziswa kwamakamelo okuhlunga ukuze kuqinisekiswe ukuhlunga okuqhubekayo.Izindlu zegumbi lokuhlunga ziphonswa ucezu olulodwa ngensimbi engagqwali.Isihlungi sendawo enkulu sakhiwe izici zesihlungi sekhandlela ezinepleyiti.Isici sokuhlunga amakhandlela sisekelwa isilinda esiyinhloko esinezimbobo, futhi ungqimba lwangaphandle lufakwe inemeshi yensimbi eyodwa noma enezendlalelo eziningi noma i-sintered metal powder disc noma i-multi-layer metal mesh & fibre sintered noma i-sintered metal wire mesh, njll. ngesilinganiso esihlukile sokuhlunga esisekelwe ezidingweni zemikhiqizo yokugcina.

Ngokuvamile kunezinhlobo ezahlukene zesistimu yokuhlunga, njengesistimu yokuhlunga eqhubekayo evundlile, isistimu yokuhlunga eqhubekayo eqondile.Isibonelo, phakathi nenqubo yokuphotha ama-PET chips, uhlobo lwesihlungi sohlobo lwekhandlela olume mpo ngokuvamile luyahlongozwa, olunendawo yokuhlunga engu-0.5㎡ umgogodla wekhandlela ngalinye.Kukhona ukucushwa okuvamise ukusetshenziswa kwamakhora ekhandlela angu-2, 3, noma angu-4, ahambisana nezindawo zokuhlunga ze-1, 1.5, noma 2㎡, futhi amandla ahambisanayo okuhlunga okuncibilika angu-150, 225, 300 kg/h.Isistimu yokuhlunga eqondile inosayizi omkhulu nokusebenza okuyinkimbinkimbi, kodwa inezinzuzo eziningi ngombono wenqubo: (1) Inamandla amakhulu okushisa, ukuhluka okuncane kwezinga lokushisa elincibilikayo, futhi azikho izindawo ezifile lapho impahla igeleza.(2) Isakhiwo sejakhethi yokuhlukanisa sinengqondo, futhi izinga lokushisa lifana.(3) Kulula ukuphakamisa umgogodla wokuhlunga lapho ushintsha isihlungi.

Umehluko wengcindezi ngaphambi nangemuva kwesihlungi esisanda kusetshenziswa uphansi.Njengoba isikhathi sokusetshenziswa sikhula, izimbobo eziphakathi nendawo zokuhlunga ziyavaleka kancane kancane.Uma umehluko wengcindezi ufinyelela inani lokusetha, isb, njengama-PET chips ukuphotha, ngokuvamile inani licishe libe ngu-5-7MPa, igumbi lokuhlunga kufanele lishintshwe.Uma umehluko wengcindezi ovunyelwe weqiwa, i-mesh yesihlungi ingase isongwe, usayizi wemeshi uyanda, futhi ukunemba kokuhlunga kuyehla kuze kube yilapho isihlungi sigqashuka.Isihlungi esishintshiwe kufanele sihlanzwe ngaphambi kokuphinda sisetshenziswe.Ukucaca komthelela kunqunywa kangcono ukuhlola "ibhamuza", kodwa kungase futhi kwahlulelwe ngokusekelwe kumehluko wengcindezi ngaphambi nangemuva kwesihlungi esisanda kushintshwa.Ngokuvamile, lapho isihlungi sekhandlela sigqashuliwe noma sihlanzwa izikhathi ezingu-10-20, akufanele sisasetshenziswa.

Isibonelo, ezihlungini zochungechunge lwe-Barmag NSF, zishiswa ngesitimu se-Biphenyl ejazini, kodwa izinga lokushisa loketshezi lokudlulisa ukushisa akufanele lidlule ku-319℃, futhi umfutho omkhulu we-Biphenyl steam ngu-0.25MPa.Ingcindezi enkulu yokuklama yegumbi lokuhlunga ngu-25MPa.Umehluko omkhulu ovunyelwe wengcindezi ngaphambi nangemuva kwesihlungi ngu-10MPa.

Imingcele Yezobuchwepheshe

| Imodeli | L | B | H | H1 | H2 | LUNGISA(H3) | I-Inlet&Outlet DN(Φ/) | Indawo yesihlungi(m2) | Ibha Eyisikulufu Esebenzayo(Φ/) | Izinga Lokugeleza Elidizayinelwe(kg/h) | Hlunga Izindlu | Isici sesihlungi | Isisindo Esiphelele(kg) |

| PF2T-0.5B | 900 | 1050 | 1350 | Njengesayithi yekhasimende | 2200 | 22 | 2x0.5 | 65 | 40-80 | Φ158x565 | Φ35x425x4 | 660 | |

| PF2T-1.05B | 900 | 1050 | 1350 | 2200 | 30 | 2x1.05 | 90 | 100-180 | Φ172x600 | Φ35x425x7 | 690 | ||

| PF2T-1.26B | 900 | 1050 | 1390 | 2240 | 30 | 2x1.26 | 105 | 150-220 | Φ178x640 | Φ35x485x7 | 770 | ||

| PF2T-1.8B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.8 | 120 | 220-320 | Φ235x620 | Φ35x425x12 | 980 | ||

| PF2T-1.95B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.95 | 130 | 250-350 | Φ235x620 | Φ35x425x13 | 990 | ||

| PF2T-2.34B | 1030 | 1200 | 1430 | 2330 | 40 | 2x2.34 | 135 | 330-420 | Φ235x690 | Φ35x485x13 | 1290 | ||

| PF2T-2.7B | 1150 | 1200 | 1440 | 2350 | 50 | 2x2.7 | 150 | 400-500 | Φ260x690 | Φ35x485x15 | 1320 | ||

| PF2T-3.5B | 1150 | 1250 | 1440 | 2350 | 50 | 2x3.5 | 160 | 500-650 | Φ285x695 | Φ35x485x19 | 1450 | ||

| PF2T-4.0B | 1150 | 1250 | 1500 | 2400 | 50 | 2x4.0 | 170 | 600-750 | Φ285x735 | Φ35x525x19 | 1500 | ||

| PF2T-4.5B | 1150 | 1250 | 1550 | 2400 | 50 | 2x4.5 | 180 | 650-900 | Φ285x785 | Φ35x575x19 | 1550 | ||

| PF2T-5.5B | 1200 | 1300 | 1500 | 2350 | 50 | 2x5.5 | 190 | 800-1000 | Φ350x755 | Φ50x500x15 | 1650 | ||